K1 Prime – Automatic Electric Fluxer

The K1 Prime: Introduction

The K1 Prime brings the ultimate in fusion accuracy together with all the advantages of electric power: controlled heating, energy efficiency and ease of installation – now with a sleek touch-screen interface, a safety shield and even more robust components than the original K1.

The K1 Prime is pre-loaded with various fusion methods that can be used as is, or can be customized. All fusion methods can be saved, renamed, deleted or copied, just like computer files. Only the preset methods are protected to avoid accidental overwriting. A standard platinum crucible is loaded with a few grams of powdered sample, an appropriate flux and often other agents. The crucible is inserted into the crucible heater, and locked by the heat reflector.

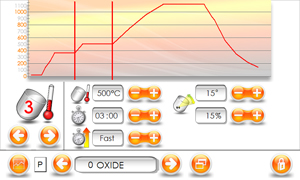

A platinum mold in a special holder is then installed in the mold heater. When the user instructs the K1 Prime to launch the fusion, electricity heats the crucible element, and all heating steps are automatically started in sequence. Temperature is constantly monitored and displayed. The tilting motion of the crucible heater continuously mixes the flux with the sample.

When the flux melts, it starts dissolving the sample. The mold heater element is then powered to prepare for pouring. When all sample is dissolved, the crucible holder tilts forward 130° from horizontal, to empty the crucible into the mold. A fan located underneath cools the mold, while the crucible is ready to start a fusion again, to gain time. When the mold is completely cooled, the user picks a perfectly homogenous glass bead, ready for analysis by XRF. For solution preparation, the hot melt is poured in an unbreakable beaker (instead of a mold), which contains an acid stirred by an optional magnetic system. |

New features

- Color LCD touch-screen interface.

- Multilingual:

- English

- French

- Spanish

- Chinese

- Russian

- “Manager” and “User” modes.

- Improved temperature control.

- Quieter running.

- USB connectivity.

- Stronger motors, sturdier electronics.

- Integrated safety shield.

Accuracy

- Entirely automated.

- Fully reproducible fusion methods.

- Completely independent heaters for crucible and mold for optimal temperature control and homogenization.

Safety

- No gases used, so no post-combustion toxic products released.

- Minimal heat dissipation (dissipates less than a hair dryer); casing remains cool to the touch; no need for a powerful vent hood.

- Uses only a regular electrical outlet.

- Integrated safety shield.

Versatility

- Prepares glass disks for XRF, but can also readily do peroxide or pyrosulfate fusions.

- Optional solution stirrer provides for solution-making ability, for ICP and AA.

- Ready to fuse with built-in methods for oxides, minerals, metals, alloys, sulfides, fluorides and more.

- Fully customizable fusion methods.

- Can make liquid and solid oxidations.

- Can be used at either 120 and 240 VAC.

Productivity

- Throughput of 5 to 7 samples/hour.

- User-adjustable holding temperature: the temperature between fusion can be maintained to minimize initial ramping time.

Simplicity

- Plug-and-play: installs in seconds.

- Intuitive, graphical interface.

- Easy menu navigation.

- Virtually maintenance-free; easy component access.

- 1-year limited warranty.

Technical specifications

| Voltages: | 110-127 VAC |

| 220-240 VAC | |

| (50-60 Hz) | |

| Power (max): | 1300 W |

| Temperature: | 20-1150°C |

| Height: | 47 cm [19″] |

| Width: | 28 cm [11″] |

| Depth: | 66 cm [26″] |

| Mass: | 30 kg [66 lbs] |

Installation

Installation is fairly simple:

- Select installation site and unpack box.

- Connect instrument to electrical wall outlet and turn on.

- Enjoy !

What is in the K1 box

- 1 fluxer (K1 main unit)

- 1 mold heating/cooling unit with 1 mold holder *

- 1 solution agitation unit with 1 Teflon beaker *

- 1 power cord

- 1 tool kit (hex keys, spare fuses…)

- 1 instruction manual

- 1 USB memory stick

| * | The mold heating/cooling unit is included with K1P-vvv–dd instruments, while the solution unit is included with K1P-vvv-S. If you want to make both glass disks and solutions, please order a K1P-vvv–dd and add item KP5000A (solution module for K1 Prime). vvv : nominal voltage of the unit (115 or 230 VAC) |